When you desire to cut natural woods, you should use ripping blades as they effortlessly slice through thin or thick pieces of wood. So, you would need various sorts of blades for a perfect wooden masterpiece.

We believe a ripping blade is crucial as it would make it easy to get the wood into shape fast enough. There are many choices on the market to pick them out of the shelf and taken home. But depending on your budget and needs, below is a list of many of the popular ones.

Table of Contents

- View Top 8 Table Saw Blades for Ripping, Below

- 1. Dewalt DW7124PT 24 Tooth Table Saw Blade for Ripping

- 2. Forrest WW07Q307100 Woodworker Table Saw Blade

- 3. Freud LU87R010 Thin Table Saw Blade

- 4. Irwin Marples 1807368 Table Saw Blade for Ripping

- 5. CMT 201.024.10 Industrial Table Ripping Saw Blade

- 6. Dewalt DW3106P5 10-Inch Table Saw Blades

- 7. Overpeak 10-Inch Ripping Table Saw Blade ATB Ultra Fine Finishing

- 8. Taichiv 40 Tooth ATB Carbide Framing Saw Blades for Timber and Wood Cutting

- Key Uses of a Ripping Table Saw Blade

- Buyer’s Guide

- Conclusion

View Top 8 Table Saw Blades for Ripping, Below

1. Dewalt DW7124PT 24 Tooth Table Saw Blade for Ripping

- Diameter: 10 inches;

- Teeth: 24(ATB);

- Kerf :3/32 inches;

- Arbor: 5/8 inches;

- Blade type: RIP & Crosscut Combo.

Dewalt DW7124PT has a premium micro-grain carbide that gives an ultra-sharp cut to reduces splinters drastically. With its premium harsh coat finish, it produces less heat and friction with a laser-cut body to provide accurate cuts.

Able to power through non-ferrous metal and plastic with ease. Additional dampening slots reduces vibration to make your woodwork reliable. Most preferred blade for ripping but also can be used for crosscutting.

This blade rated excellent on many sites having words such as “Best by far for ripping very hardwood” make much sense as its a solid buy for a low price tag. Lasts longer than most cheap blades out there. Rips very well compared to multi-purpose blades.

Pros:

- Has a slightly steeper hook angle of 20 degrees;

- Ample space between teeth;

- The ATB oriented teeth;

- A thin kerf blade.

Cons:

- It does not work well on the hardwood;

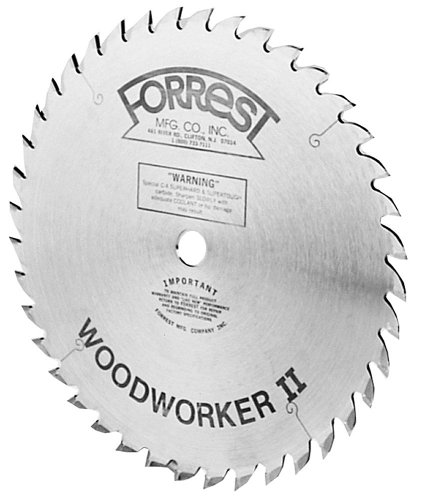

2. Forrest WW07Q307100 Woodworker Table Saw Blade

- Diameter: 5/8 inches;

- Teeth:30;

- Kerf:3/32 inches;

- Arbor:5/8 inches;

- Tooth style: ATB;

- Blade type: RIP & Crosscut combo.

This premium carbide-tipped blade from Forrest claims to be 40% stronger and harder while giving itself up to 300% longevity. At the End of your cut, it should leave a smooth edge, feeling like sanded and polished. Perfect for the all-purpose blade.

Many buyers reviewed it as a 5-star product and mention “smooth cuts” as it costs more than most regular blades but seem extraordinary. “Clean cuts” with mentions of “being the best for a reason.”

This blade runs very silently, and each one is practically hand-made. The plate is hand-tensioned up to 15 minutes. The superior C-4 carbide teeth are hand-brazed to the plate and stretch multiple times throughout the process.

Pros:

- 300% Longevity;

- 40% Stronger;

- Leaves cuts like it were sanded and polished;

- Perfect for all-purpose blade;

- Worth every penny for the performance it gives out.

Cons:

- Sometimes it burns and causes an accident;

- Higher price tag.

3. Freud LU87R010 Thin Table Saw Blade

- Diameter: 10 inches;

- Teeth: 24;

- Kerf: 0.094 inches;

- Arbor: 5/8 inches;

- Tooth style: FTG saw.

Freud LU87R010 thin kerf rip saw blade has a 10-inch diameter, 5/8-inch arbour, 24-tooth design to deliver high-quality work. It can formulate each tool for each specific application to maximizing the cutting life and performance of the device.

Featuring a premium TiCo Hi-density carbide blend for highest performance and its HiATB design produces splinter-free cuts. It’s Perma Shield nonstick coating minimizes blade drag and protects it from corrosion.

Additionally, anti-vibration design reduces chatter for a cleaner finish, longer blade life, and reduced noise at the workplace. Though the blade is laser cut from high-strength steel, it will stay stable, flat, and accurate, even after prolonged use.

Pros:

- TiCo Hi-density carbide with titanium construction;

- Contains cobalt and tungsten for a durable finish;

- Thin kerf allowing it to be power;

- Laser-cut anti-vibration slots;

- Non-stick perma-shield coating to resist heat;

- Stays aligned after high usage.

Cons:

- Found sometimes with blade defects;

- Doesn’t work well on chipboard or laminates material.

4. Irwin Marples 1807368 Table Saw Blade for Ripping

- Diameter:10 inches;

- Teeth:50;

- Kerf: 098 inches;

- Arbor:5/8 inches;

- Tooth Style: HiATB.

If looking for the perfect table saw blades for ripping, Irwin 1807368 is ideal with a ten-inch diameter and a standard 5/8 arbour. It comes with a thin kerf of 098, so before a working check, the blade works with a riping knife and a splinter.

This 50-teeth blade engineered with oversized, high-quality carbide, which provides the extended life and flawless finish to professional woodworkers and carpenters.

The blades are precision tensioned for flawless cuts. They also feature a heat resistant, nonstick coating with an aluminum matrix added to it to dissipate heat for easy cleanup and more accurate, cleaner cuts.

This blade is ideal for both crosscutting and ripping on a table saw. The module is suitable for softwoods, hardwoods, composite materials, pressure-treated lumber and plywood.

Pros:

- 10 inches 50-teeth blade;

- Heat resistant and nonstick coating;

- An alternate top bevel;

- Ideal for both crosscutting and ripping;

- It does a great job cutting various materials.

Cons:

- The speed of the blade is deficient;

- Some teeth can break off when making cuts.

5. CMT 201.024.10 Industrial Table Ripping Saw Blade

- Diameter:10 inches;

- Teeth: 24;

- Kerf: 0126;

- Arbor: 5/8 inches;

- Tooth style: FTG;

- Blade Type: Ripping only.

CMT 201.024.10 10-inch, 24-tooth table saw blade is equally perfect at home performing crosscuts and professional ripping cut in hard and softwood. The price is affordable and within reach of most DIY people. Out of the box, the blade was straight and accurate, as you’d hope to see.

Micrograin carbide teeth last longer and deliver smooth cuts on soft or hardwood. PTFE nonstick coating keeps the blade cool and protects against corrosion. It is made of premium German Steel to ensure reliable cutting performance.

For more robust work, the kerf thickness is 0126 and plate thickness is 0087 to provide durable cut. Moreover, a 20° hook angle gives flexibility at work. These blades are equipped with a unique anti-kickback joint behind each tooth to minimize the possibility of dangerous kickback.

Pros:

- Fast cuts through soft or hardwood;

- Micro-grain carbide teeth;

- Keeps its sharpness for an extended period;

- PTFE nonstick coating resists the blade from heating;

- Made of premium German steel;

- Anti-kickback shoulders.

Cons

- Some cuts can be rough;

- Louder than other models.

6. Dewalt DW3106P5 10-Inch Table Saw Blades

- Diameter: 10 inches;

- Teeth:60;

- Kerf: 3/32 inches;

- Arbor: 5/8 inches;

- Tooth style: ATB;

- Blade Type: Crosscutting only.

The Dewalt DW3106P5 comes with an attractive offer of two blades for the price of one, which is excellent if the blades live up to their potential. One with 32 teeth for ripping or other general-purpose tasks, and the other with 60 teeth for high-quality crosscutting.

These blades are made by a computer-balanced plate that reduces vibration and leads to increased accuracy and a better finish. The unique wedge shoulder design produces a smooth finish with very little waste.

Ultra-sharp construction carbide lives up to heavy-duty use and able to provide clean cuts, finely carves through the material because of its thin kerf, leaving a smooth cut quickly. Capable of performing on varieties of wood crosscuts, slices through plywood, chip wood, hardwood and softwood.

Pros:

- Thin kerf more power-efficient;

- Minimal vibration for better accuracy;

- Wedge shoulder design;

- Finishes the job with clean cuts;

- Ultra-sharp construction to ensure actual cuts quickly;

- Can withstand heavy-duty cuts.

Cons:

- Chances of burning work;

- Possibility of worn-out teeth after heavy use.

7. Overpeak 10-Inch Ripping Table Saw Blade ATB Ultra Fine Finishing

- Diameter: 10 inches;

- Teeth: 90;

- Arbor: 5/8 inches;

- Tooth style: ATB;

- 4 sided ground blade.

With a top of 6,000 RPM, this Overpeak table saw a ripping blade that can use in almost any saw. Making it even handier is the variety of tooth options available, from 30-90 TPI. It’s a little expensive than some of its most similar competitors, though we don’t feel that it provides extra value.

It supposed to be a thin kerf blade but practically thicker than other blades. It is crafted from tungsten-carbide to cut material very quickly. Six laser-cut expansion slots and four laser-cut stabilizer vents trap noise and vibration to keep it cool and reduce blade warp.

This 10-inch carbide blade is suitable for ripping wood, crosscuts wood, plywood, and laminate work. This table saw blade leaves so smooth cut that you may think it has sanded by 600 grit sandpaper.

Pros:

- Heat resistance material reducing blade wrapping;

- 10 inches alternate-top bevel teeth;

- Best suites for table saw;

- RPM up to 6000;

- Low noise.

Cons:

- Little overpriced;

- Not delivers the cleanest cuts.

8. Taichiv 40 Tooth ATB Carbide Framing Saw Blades for Timber and Wood Cutting

- Diameter: 10 inches;

- Teeth: 40/60/80;

- Arbor: 5/8 inches;

- Tooth style: ATB;

- Non-stick Perma-shield coating.

Taichiv 40 tooth ATB Carbide saw blade is an all-purpose blade, especially for ripping. It perfectly fits on circular saws, mitre saws, and table saws. The module can operate up to 5,500 RPM, making it easy to cut timber both hardwood and softwood. It is well-designed to maximize the accuracy of the cuts.

The 40- tooth blade creates severe and bevel cuts correctly to make an artistic cut. The module has a 5/8 arbour enhanced with a diamond knockout.

The carbide material made by ultra-coated and nonstick Perma- shield to enhance the durability. These materials used to coat the blade prevent corrosion, rust, and remove excess heat for easy cleaning.

It is well-engineered to handle softwood safely without cracking or splintering. The teeth are in a set with a gullet for separating chips.

Pros:

- Perfectly fits on table, circular and handsaws;

- Designed to slice all categories of timber;

- Made using Tungsten carbide;

- It rotates at high speed of up to 5,500 RPM.

Cons:

- The cut may not be as smooth as reviewed.

Key Uses of a Ripping Table Saw Blade

- To quickly cut many wood pieces to Shape or Size;

- Cut thick slices of hardwood;

- To have a smooth and professional cut;

- Substantial cuts through the long grain.

Buyer’s Guide

If you want to reduce the amount of wood waste while cutting and for better control, it is essential to know some features that a perfect table saw blade should have. Those are below:

Types of Blade

You can find severe types of a module with an acronym in the market. But you will get puzzled if you don’t know the acronym and its usage. Alternate Top Bevel(ATB), Alternate Top Bevel with Raker(ATBR), High Alternate Top Bevel(HATB), Flat Top Grind(FTG) and Triple-Chip Grind(TCG) are some blade types which used in different types material. These will stand for the name of a tooth that the blade has.

Numbers of Teeth

It’s good to understand how the number of teeth in a saw blade will affect the cut. As a general custom, we know the more teeth on a knife, the smoother the cut. Flat Top Grind(FTG) blade has 40 to 50 teeth, the ATBR blade has 40 to 80 teeth, and the TCG blade has 80 teeth in general.

Ripping blades have fewer teeth as they designed to give a quick cut along the grain of the wood. On the other hand, crosscut modules designed across the grain of the wood without splintering.

Kerf

Kerf is mainly known as the width of the blade that cuts. Thin kerf blades require less power to operate and eliminate less content than a full kerf blade.

Keep notice that the blade with thin kerf could bend or vibrate a bit more than some of the thicker kerf options.

Blade Size

You will get frustrated when you choose a larger or smaller blade that wouldn’t fit your table saw. So before buying a blade, always measure which size will fit your saw. Usually, different blades to perform well is used in table saw, so it is advisable to check thoroughly.

Types of Cuts

Different blade shapes produce better-quality cuts. If you want a perfectly straight cut and free of splinters, you’ll have to use different blades depending on the adjustment with the table saw. Various types of popular cuts are-Cross cut, Bevel cut, Meter cut , Compound cut and many more. All these cuts need different blades to perform well.

For example, when you’re making rip cuts, you’ll want a blade with fewer, but larger, teeth. If you’re looking for something decent, you can take a 40 or 50 tooth blade. But remember that those will be combination blades.

Conclusion

This review aims to enlighten prospective buyer’s knowledge of what they need to look for when purchasing a table saw blade for ripping.

We hope all of the reviews above has been a great help for you to choose the right product. Always consider the cuts and material before buying a table saw blades for better results.