Many craftsmen see saws as a must-have tool in their inventory. Over the years, there have been many different types of saws constructed to fit various niches and uses.

Enthusiasts will often closely follow the new ones and add them to their collection. However, there are so many different types of saws for woodworking that it can be hard to keep track.

How can this article help you then? Here, a rundown of the various kinds of saws for cutting wood is given. I’ll explore all types of hand saws, electric saws, and power saws. You’ll find out their different niches and uses and have access to all this information in one article. So, let’s dive in.

Table of Contents

Basic Saw Types

The primary types of saws you will come across are mainly of 2 types:

- Hand Saws

- Power Saws

Seeing those names, you might be wondering what separates them from each other. Let’s look at them one at a time and try to get a good grasp of their classification.

1. Hand Saws

The easiest way to identify a typical hand saw is by seeing whether it makes use of an external power source or not. If it doesn’t, it can be classified as a hand saw. Hand saws are alternatively known as panel saws.

Hand saws aren’t very complex, usually featuring a handle and variations in the blade. The variations in the blade help to define their various niches.

2. Power/ Electric Saws

These saws make use of an external power source and can be battery powered. There are corded and cordless versions. They find more use in doing heavy-duty work and are seen in factories where large amounts of steel or wood need to be cut according to precise measurements.

Different Types of Saws for Woodworking & Their Uses

I’ll now list and give you a tour through the different kinds of saws. Using the general classification set above, the list will categorize the saws.

Different Types of Hand Saws & Their Uses

Hand saws are prized for their convenience and accuracy. They rely on the strength of their user but allow for the most control out of all the basic saw types.

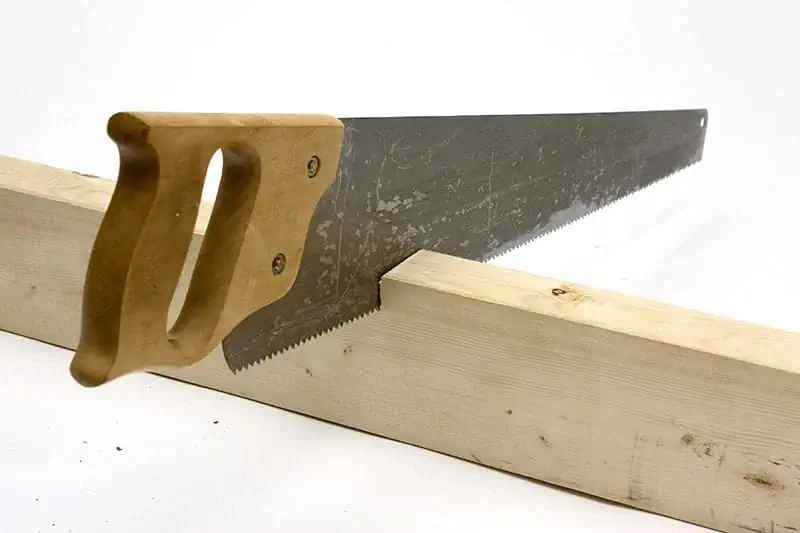

1. Basic Hand Saw

A basic hand saw is a tool that I would recommend most experienced workers to either have or invest in. It doesn’t have much flair, but it is reliable. The flexible blade often has variations in its teeth to allow for different uses. This is useful for its main purpose, which is cutting wood.

Generally, you can find basic hand saws with:

- Rip Teeth: They are the most common. You can use them for cutting wood while following the grain. If you need to saw wooden boards to a particular measurement, I recommend this.

- Crosscut Teeth: These are used for making crosscuts and cutting joints. They make for clean cuts across the woodgrain.

- Dual-purpose Teeth: Combines the features of both the previous types of teeth.

What is a basic hand saw used for?

The flexible blade is primarily used in cutting wood. And the different teeth allow for making different types of cuts. If you are primarily into woodworking, then I will recommend that you have a basic hand saw at all times. It allows a great deal of accuracy, which is essential for woodworks and crafting.

2. Rip-Cut Saw

A variation of the basic hand saw, rip cut saws feature a similar design. The difference is in their blades, which contain more teeth, and they are much sharper. The angled teeth work to make straight or rip cuts.

What is a rip-cut saw used for?

This type of saw is very useful for making straight cuts. Sawmills make use of this saw to cut wood planks and boards to a particular length or measurement.

3. Hacksaw

The hacksaw differs from your basic hand saw quite a bit. It features a flexible back instead of a handle (usually making use of a pistol grip instead). The blade is thinner and attached to the back. While the blade looks thinner, it is much stronger and harder.

Most hacksaws feature adjustable frames that allow you to change the blade sizes. You can also mount the blade with the teeth either facing away or towards the handle. This allows cutting action on the push or pull action, respectively.

What is a hacksaw used for?

The primary use for hacksaws has always been for cutting metal. Its blade is held under tension due to the design, allowing it to cut through steel. Metalworkers often have a hacksaw or its electric saw variant.

Aside from metal, it can also be used to cut plastic. So, plumbers will often employ hacksaws to cut plastic pipes.

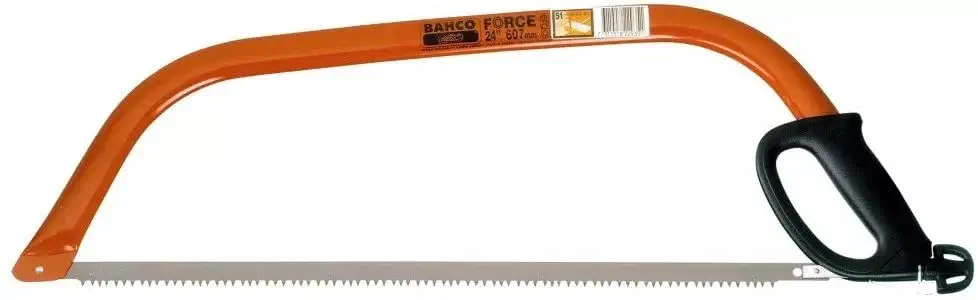

4. Bow Saw

The bow saw resembles a bow, but instead of a drawstring, it features a saw blade. The blade is thin and held in tension with a turnbuckle, which improves its cutting power. The design allows for both straight and curved cuts.

What is a bow saw used for?

The blade held in tension can cut through thick sections of wood. They can be used to make curved cuts or crosscuts.

5. Lumberjack Saw

This saw is a bit different compared to the last two. The most noticeable thing is that this saw has two handles. Unlike the previous saws, a lumberjack saw is meant to be used by two people together.

Aside from it having two handles, another thing to note is that the teeth of the blade are designed a bit differently. This allows sawdust to fall through the teeth. It allows for clean cuts, which are important for cutting down trees. The well-crafted edge makes it more efficient.

What is a lumberjack saw used for?

Just like its name suggests, a lumberjack saw is primarily used for cutting down trees for lumber. Its design is made with that task in mind. Cutting trees takes a lot of strength, so the double handles allow two people to use it, making the task easier.

The saw can also be used for sawing a plank as a basic hand saw. I would suggest to not make use of the second handle for this task as it will give you an easier time.

6. Pruning Saw

Pruning saws, at first glance, look more like an oversized knife. They have a curved blade and a knife-like handle. These have more teeth per inch than most hand saws. Their general design makes them longer than other hand saws, which helps them to reach and cut branches.

What is a purning saw used for?

A pruning saw is a gardener’s best friend. The knife-like handle allows it to be handled easily and makes it useful to cut down shrubberies and vines. Its curved blade and the numerous teeth allow it to be good at pruning. The length allows the user to reach branches.

7. Folding Saw

There is another popular variation of the pruning saw, which is a folding saw. It features much of the same design principle, only being smaller in size. The foldable blade allows them to be carried around more easily and can save space in your storage.

What is a folding saw used for?

Folding saws are used more for similar purposes. The portability factor is the main advantage of owning a folding saw because they are easier to carry around. If you are a gardener, you might benefit greatly from having a folding saw to take care of overgrown shrubs. Gardeners often keep them in their pockets to cut small shrubs or vines to size.

8. Razor Saw

It’s a small saw that can be kept on hand. They often feature replaceable blades with the blades consisting of small crosscut teeth.

What is a razor saw used for?

Due to the small size of the razor saw, it doesn’t see much use. Some craftsmen tend to have it on hand as the size and shape allow easier cutting and curving of softwoods. It can also cut through plastic, so it can be used to shape plastic.

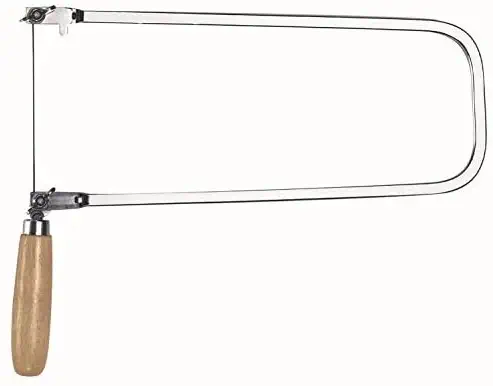

9. Coping Saw

The coping saw looks similar to the hacksaw. The difference is that the frame of the coping saw is much larger, and the steel blade is thicker.

This interesting design allows it to cut curves into the wood. Also, this saw cuts on the pull stroke since it has a fixed blade.

What is a coping saw used for?

The primary uses of these saws are in wood crafting, particularly scribing in wood. The design allows the user to rotate the blade using the handle and carve the patterns on to the wood.

10. Fret Saw

Another type of saw is the fret saw. The fret saw is also similar in appearance to the coping saw but with an even larger frame and thinner blade. If you need tighter curves or more precise crafting, I would suggest using a fret saw over a coping saw.

What is a fret saw used for?

Fret saws are named after a particularly decorative design known as fretwork. You will see this type of design on most furniture and wooden musical instruments. Fret saws are used by experienced craftsmen as they can be difficult to use.

Stronger blades on this saw can allow them to carve designs on metals like aluminum.

11. Keyhole Saw

Featuring a dagger-like blade, a sharp point, and a gun like grip, the keyhole saw is a niche saw but a useful one. The particular design is meant to help the user reach more awkward and hard to reach places. They aren’t too big and sometimes come with retractable blades to make them easier to carry.

What is a keyhole saw used for?

The keyhole saw gives you more control and is generally used more like a carving knife. If you want to cut out shapes in the wood, then a keyhole saw will easily allow for that. I would recommend this for hobbyists who like to carve wood. The retractable versions are very easy to carry and store.

12. Wallboard Saw

Resembling a knife and having teeth lined on both sides of the blade, the wallboard saw is very useful for home renovation. The sharp tip and doubled toothed blade allow both easy penetrations of drywalls and smooth cutting.

Having a wallboard saw can make it so you don’t need to drill holes into your drywall.

What is a wallboard saw used for?

Interior decorators or home renovators tend to have wallboard saw at hand. They are small and easy to carry. Drywalls and floorboards are the general targets for this saw.

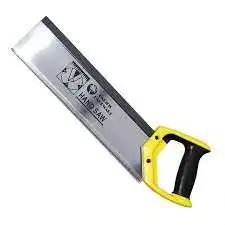

13. Back Saw

Back saws have thin, stiff blades. Most versions of the back saw have a stiffening cap over the top edge of the blade along with specially designed handles. The stiffening rib is made out of brass or steel and keeps the blade straight, adding more weight to the cut.

What is a back saw used for?

These types of hand saws allow for greater control and precision cutting. They are used in cabinetry and joinery to make precise and angled cuts to form joints.

14. Tenon Saw /Carcass Saw

Tenon saws are alternatively known as carcass saws. These are a bigger variation of back saws featuring much of the same design principle. The difference is in the blade having much finer teeth and a higher density of teeth.

What is a tenon saw used for?

They are used for rip cutting and cross-cutting. Tenon joints, as the name suggests, are best made using this saw.

15. Veneer Saw

The veneer saw is a much smaller hand saw compared to the other saws on the list. Now, the blade of the veneer saw is double-edged but has no teeth with the blade being curved. Also, the handle of the veneer saw is elevated.

What is a veneer saw used for?

It finds use in wood veneering. The blade is perfect, making square cuts on thin hardwood pieces and is often used to shape wood for doors.

16. Japanese Saw

The claim to fame for Japanese saws is that they are the best saws to cut on the pull stroke. These saws have much thinner blades so they can make much narrower cuts. Some of the blades are double-edged, and some have a stiffening rib attached.

What is a japanese saw used for?

Japanese saws can make thinner cuts, so there is no tearing of the grain. These saws work the best on softwoods like pine. They have difficulty cutting through hardwood due to the thinner blade.

Read More: Best Japanese Flush Cut Saw

17. Wire Saw

Wire saws might be the most different hand saws you’ll see on this list. Instead of making use of saw teeth to cut through material, they use abrasion. They consist of a wire and two handles. You wrap the wire around an object and move the handles to cut into the object using the abrasiveness of the wire.

What is a wire saw used for?

Wire saws are quite a niche, particularly because they can take some time to cut objects and can strain you. Their main advantage is that they are small and lightweight and can be carried around easily for cutting small pieces of wood.

18. Pole Saw

At first glance, a pole saw might resemble a spear of sorts. The handle of the pole saw is the largest out of all the hand saws. The blade of the pole saw is similar to that of a pruning saw.

What is a pole saw used for?

The handle of the pole saw allows you to reach high places using it. So, you can cut off higher branches using a pole saw, where you probably couldn’t use a pruning saw.

19. Camping Saw

Camping saws are portable hand saws that often come with a sheath. They are lightweight and portable. The sheath can be used to lock the blade in place to make cutting easier.

What is a camping saw used for?

As the name suggests, camping saws are very helpful for campers. They can be used for trimming trees or bushes and also cutting up firewood.

20. Bone Saw

Bone saws feature a stainless steel blade and look more like a butcher’s knife than your regular hand saw. The blade is very sharp and can cut through bone with little force. They have a unique handle for proper grip and guard.

What is a bone saw used for?

They are used to cut through carcass and bones. Hunters often keep them close when they go out hunting for deer.

Different Types of Power Saws & Their Uses

Power saws are the most powerful of the bunch. They’re used for heavy-duty and large scale tasks. Below, we’ll go through different types of power saws.

1. Chainsaw

When normal wood cutting tools aren’t cutting it, chainsaws are a good answer. They are much more powerful than all the hand saws while being very efficient. There are both gas-powered and electric-powered chainsaws. Each has its different advantages.

What is a chainsaw used for?

Chainsaws are fast at cutting large amounts of wood. They can easily cut down trees for lumber. However, they do not cut smoothly and do not have much control, so they cannot be used for any work involving precision.

2. Reciprocating Saw

Reciprocating saws get their name from how their cutting mechanism works. The blade moves back and forth in a repeated motion to cut through the material. And the cuts they make are rough, but they are very fast and efficient at cutting.

Both corded and cordless versions of these saws are available. Like chainsaws, corded versions are much more powerful but can’t be taken everywhere. It should also be noted that getting tangled in cords can get you hurt, so always line out the cord properly.

While reciprocating saws are good at making fast and rough cuts, some come with orbital action. This makes the blade move both up and down and side to side, increasing the cutting power.

What is a reciprocating saw used for?

Reciprocating saws are powerful and can cut through hardwood, masonry, metals, and fiberglass, provided they are fitted with the right blade. However, precision cuts are not their strong points.

I’ve seen them make a mess out of most cuts, so if you need to cut down lots of lumber in a short time and aren’t worried about how they turn out, then reciprocating saws are very helpful.

3. Jigsaw

The first noticeable thing about a jigsaw is that the blade points downwards. A large handle featuring a trigger allows good control over the saw. This leads to the defining feature of jigsaws.

They are a good mix of power and control, and unlike the two electric saws we’ve covered, it allows for accuracy. So, you can make curved cuts. They similarly come in corded and cordless versions.

What is a jigsaw used for?

In my experience, jigsaws are one of the most versatile electric saws available. This is primarily because of how easier it is to control them. You can make curved cuts on plastic, wood, ceramic, and even metals if you have the right tools.

They also see use in home renovation, particularly in installing countertops. Either way, I would suggest this particular electric saw to anyone interested as it is very useful.

Read More:

Best Jigsaw

Best Corded Jigsaw

4. Rotary Saw

These saws are unique, and their design makes them very versatile. They are much smaller than the other electric saws covered. While it is called a saw, it works more like a drill but still works to cut through various materials.

They have a good mix of power and control. Their size allows them to be used using one hand. They generally make use of carbide-tipped blades.

What is a rotary saw used for?

The ease of use and control allows rotary saws to make patterns on wood. Depending on the blade, they can also perform this task on metals like aluminum. They can also be used to sand wood.

Due to the unique rotary motions, rotary saws are a lot more versatile. They can be used to remove old paint and varnish.

5. Table Saw

It’s hard to find a woodworker’s workshop without a table saw. They consist of a table and a stationary saw that cuts wood as it is passed through it. The saw moves very fast and can cut through wood easily.

You can see it being used in many woodworking industries where they are used for cutting large pieces of wood. They make use of large 3 Horsepower motors.

While the table saw can be used to make normal cuts, it can also be fitted with different gauges and tools like miter gauges. This allows the table saw to make crosscuts and angled cuts.

So, table saws can be made very versatile. I would recommend fitting your table saw with some safety features like a riving knife to reduce kickback.

What is a table saw used for?

Table saws are mostly used for cutting wood. When fitted properly, they can make different types of cuts. Woodworkers will benefit from having table saws as they are very useful.

6. Flooring Saw

Flooring saws are similar to table saws but are specifically made to cut floorboards. They can be placed on floors, and the saw can be run through to cut the floorboards. Their design makes them very stable.

What is a flooring saw used for?

They are relegated to flooring jobs as they make those tasks fast and easy. They do not have the same level of control and flexibility as table saws, which limits their use.

7. Panel Saw

Panel saws are, in essence, much bigger table saws. Their size and cutting power enable them to cut large metal sheets to appropriate measurements. They are mostly stationary saws.

What is a panel saw used for?

They are used in large-scale metalworking industries to cut large sheets of metal. The saw blades used are very powerful, and they can cut fast and accurately.

8. Miter Saw

Miter saws are more specialized power saws. They are used to make miter cuts or angled cuts and specialized in that. It consists of a large revolving saw blade on a fixed arm with a table to mount the material on. Using the miter gauge on the machine, you can adjust the angle of the cut.

What is a miter saw used for?

The main use of miter saws is to make angled cuts. This is important in woodworking, as for making furniture and cabinets you will sometimes need to make angled cuts. Miter saws work on plywood and plastic.

9. Radial Arm Saw

Radial arm saws are a cheaper option to miter saws. They consist of a movable horizontal arm, and a circular saw is mounted on it. It works similar to miter saws where material needs to be mounted on the table.

What is a radial arm saw used for?

They have the same uses as miter saws but are a bit slow to operate. They are mainly used as a cheaper alternative.

10. Oscillating Saw

Oscillating saws are smaller and lightweight power saws. Their blades are very powerful and changeable, allowing them to tackle many different types of materials. It has a long handle allowing for easy grip.

What is an oscillating saw used for?

The main advantage of oscillating saws is that they are small and can be used to reach tight and awkward places. The variety of blades allow them to cut through drywall, plastic, metal, and wood.

11. Chop Saw

Chop saws are somewhat similar to miter saws in that they can make angled cuts. The difference is that chop saws make use of a highly abrasive blade, which rotates very fast. This allows them to cut through metal, which miter saws can’t. So, they are a much more powerful version of miter saws.

What is a chop saw used for?

The advantage of chop saws is that they can cut through metal. So, if you want to make angled cuts on your metal, chop saws are very helpful for it. Construction and metalworking industries make use of chop saws the most.

12. Circular Saw

If I could sum up circular saws, I would say they are portable table saws. Unlike table saws, they aren’t stuck to a particular table and instead can be mounted on surfaces. They are powerful and can cut through wood and metal easily.

To use a circular saw, you need to make sure the material you want to cut is held stationary. Mount the circular saw and move it through the material to cut through it.

What is a circular saw used for?

A circular saw is very powerful and can cut through both wood and metal. Since they don’t make use of a table, you can cut longer pieces of wood or metal. Woodworkers can make use of them as a portable alternative to table saws.

13. Masonry Saw /Concrete Saw

Masonry saws are also known as concrete saws and feature a diamond-tipped saw blade. Although they look like circular saws, they are much more powerful. They have a water cooling system due to the massive amount of friction their work generates, which causes immense heat.

What is a masonry saw used for?

These saws are powerful enough to cut through a concrete slab. Thus, they can be used to shape and cut through cement and concrete. As a result, they see use in heavy construction work.

Read More: Best Concrete Saw

14. Band Saw

Band saws are unique, as you might notice, since their blades are continuous loops of metal. They use abrasion to cut through the material. This unique design allows controlled uniform cutting action. It features a table or clamp to hold the material.

What is a band saw used for?

Band saws have many uses and are quite versatile. They can cut through metal and wood alike. They offer a great degree of control so they can cut shapes and designs.

15. Scroll Saw

The scroll saw features a movable hand with a saw blade and a circular table, over which the material is mounted. It has a unique blade that works similar to a reciprocating saw. The saw has variable speed options and is very easy to control.

What is a scroll saw used for?

Since it features variable operating speeds and a great degree of control due to the movable hand, scroll saws are a very good power saw option to carve wood. The uniquely designed blade allows for waves and curls to be crafted easily on wood, allowing for decorative work.

16. Track Saw

Track saws are specialized circular saws that make use of a long set track to operate. Also, they make use of a guide rail to operate them. These are also known as plunge saws since they plunge into the material at a certain depth. This reduces splintering and tear-out.

What is a track saw used for?

They are very safe to use and can cut through materials very quickly. Projects that need more polish will make use of track saw. However, track saws offer the least amount of control.

17. Tile Saw

Tile saws are saws specialized in cutting tiles. They have a built-in water reservoir near the saw blade. The water coating onto the saw blade makes it able to cut through ceramic tiles with ease. They make smooth and straight cuts.

What is a tile saw used for?

Their use is limited to cutting tiles, but they are very good at their niche. Tile setters and home renovators will make use of tile saws since they make an otherwise difficult task very fast and smooth.

Conclusion

As you can see, there are many different types of saws for cutting trees. The purpose of this article was to highlight and compile them together. You can use this as a reference or guide to find out what the different saw types specialize in.

Hopefully, people who were confused about what saws to use now have an easier time, thanks to this article. However, be careful when using them, especially power and electric saws.